Why Steel (Fe) is Replacing Lead in Wheel Weights: A Complete Guide

For decades, lead was the primary material used for wheel balance weights, but in recent years, steel (iron) has gradually replaced lead. This change is driven not only by environmental and health concerns but also by multiple factors including performance, cost, and regulations.

1. Environmental and health impacts

- Lead Toxicity: Lead is a toxic metal, and prolonged contact with or inhalation of lead dust can pose serious threats to human health, especially to children and pregnant women. Lead exposure can cause nervous systemdamage, intellectual developmental delays, and other health problems.

- Environmental Regulations: Many countries and regions have implemented strict environmental regulations to restrict the use of lead. For example, the EU's REACH regulation prohibits the use of lead and other hazardous substances, requiring manufacturers to find non-toxic alternative materials.

- Waste disposal:Lead can contaminate soil and water during the waste disposal process, while steel (iron), as a recyclable and environmentally friendly material, is easier to reuse in waste management.

2. Physical properties of steel (iron)

- Higher Density:Steel has a density close to that of lead, but its strength and hardness far exceed those of lead. This means that steel materials can provide better balance and more uniform and stable weight distribution in the same volume.

- Durability and Corrosion Resistance: Steel (iron) materials have higher corrosion resistance, especially under extreme weather conditions. Lead, on the other hand, is easily affected by environmental factors and corrodes, leading to decreased performance.

- Machinability: Steel (iron) is easier to process into various shapes and sizes, making it suitable for many different types of tires and wheels, and at a lower processing cost.

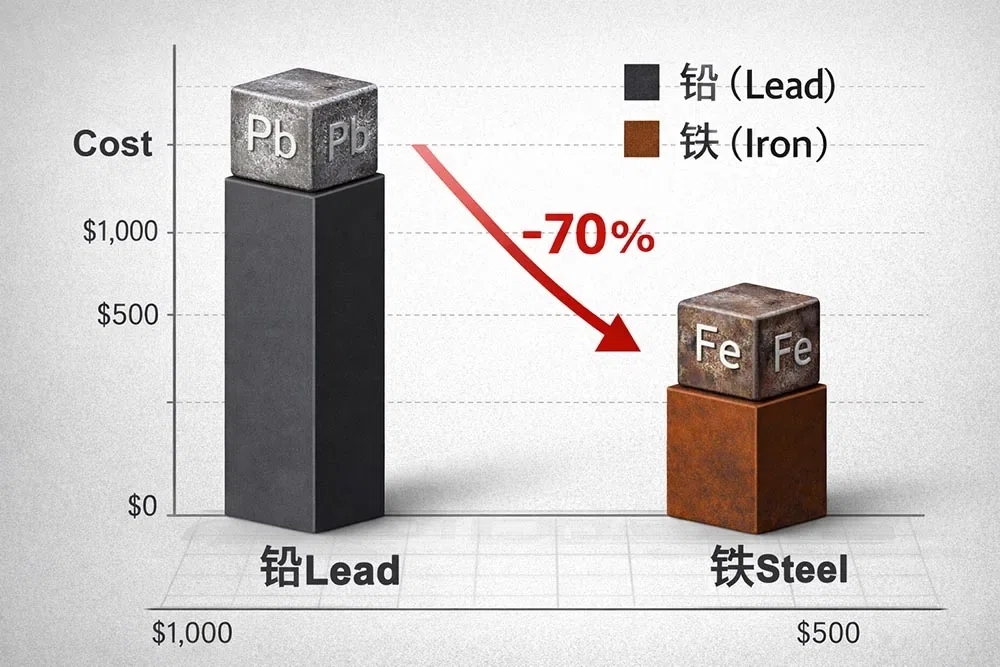

3. Cost-effectiveness

- Low cost of steel: Compared to lead, steel is less expensive, making steel wheel balance weights more economical to produce. The widespread use of steel keeps its price stable, while lead prices fluctuate significantly, increasing production uncertainty.

- Production efficiency: The manufacturing process for steel (iron) balance weights is mature, and they can be mass-produced efficiently to meet market demand for wheel balance weights. In contrast, lead requires more complex processing and is more difficult to manufacture.

4. Changes in regulations and industry standards

- Global Policy Changes: With increasing global emphasis on environmental protection and human health, many countries and regions have begun implementing lead bans or imposing strict limits. For example, the automotive industry in the United States and Europe is actively promoting the use of lead-free materials to meet environmental requirements.

- Adaptability of the Automotive Industry: Automotive manufacturers are increasingly opting for components that meet environmental standards. Therefore, steel (iron) materials, as an environmentally friendly alternative, are being adopted by more and more automotive manufacturers.

5. Recycling and reuse

- Recyclability of Steel: Steel (iron) is one of the most recyclable materials in the world, capable of being recycled almost indefinitely. This makes steel wheel balance weights more aligned with the principles of sustainable development. In contrast, the recycling process for lead is complex and incomplete, and its disposal after use is more challenging.

- Economic and Environmental Benefits: Using steel wheel balance weights not only reduces resource waste but also lowers energy consumption and carbon emissions during the manufacturing process, promoting environmental protection.

6. Consumer perception

- Increased health awareness: Consumers are increasingly concerned about the safety and environmental friendliness of products. Car owners and consumers are paying more attention to non-toxic and environmentally friendly materials when choosing wheel accessories. The use of steel (iron) materials not only meets this demand but also enhances the brand's sense of social responsibility.

7. The widespread use of steel wheel balance weights

- Wide Applicability:Steel (iron) wheel balance weights are suitable for a variety of vehicle types, including passenger cars, commercial vehicles, and heavy-duty trucks. With technological advancements, steel balance weights can be customized to meet different needs, ensuring compatibility with various wheel types.

- User Experience: Steel (iron) balance weights provide stable and long-lasting balancing effects, improving vehicle handling, reducing tire wear, and thus extending the lifespan of the wheels.

Summary

The reasons why steel (iron) is gradually replacing lead as a material for wheel balance weights are multifaceted. Firstly, steel (iron) is safer and more environmentally friendly than lead, avoiding the toxicity of lead and its environmental pollution. Secondly, steel materials possess better physical properties and lower production costs, making them a more economically viable option. Furthermore, increasingly stringent global environmental regulations and growing consumer concern for health are driving the automotive industry to transition to more environmentally friendly materials. With the widespread adoption of steel (iron) wheel balance weights, car owners and manufacturers can benefit from better cost-effectiveness, longer service life, and an improved driving experience.