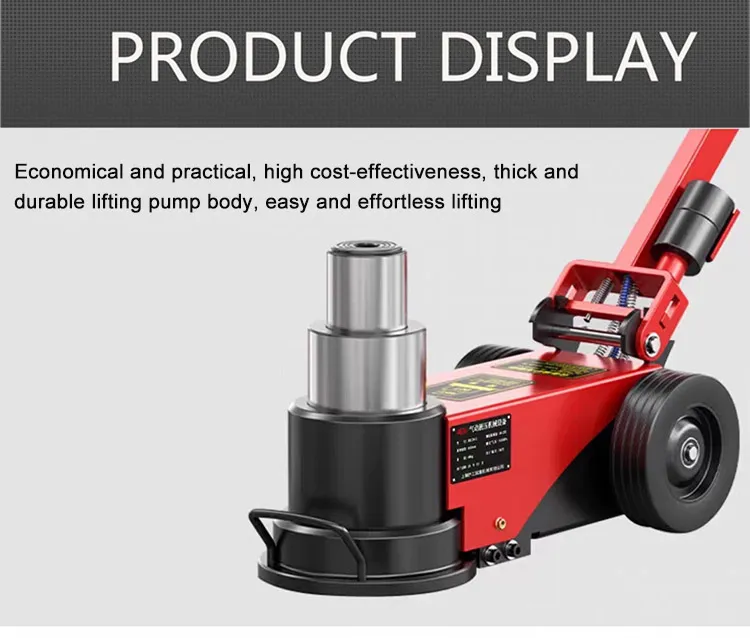

Horizontal Pneumatic Jacks Hydraulic Jacks Auto Repair Jacks

Auto Repair Jacks

| Capactity | 100/50T |

| Air Pressure | 0.8-1.2Mpa |

| Minimum height | 195mm |

| Lift | 385mm |

| Extebsion height | 35mm 65mm |

| Rated Pressure | 31.2Mpa |

| Net Weight | 82kg |

Horizontal Hydraulic Jacks Precautions

1. Estimate the weight of the object before lifting; never overload.

2. Determine the center of gravity of the object and select the appropriate jack's charging point. Place the jack on a stable surface, considering the hardness of the ground. If necessary, place it on a sturdy wooden board to prevent tilting or tipping during lifting.

3. Use air pressure within the rated range (8-12 PA) to avoid overloading the equipment and affecting its lifespan.

4. During operation, high-pressure air hoses must not be bent forcefully, dragged, rubbed against, or crushed by heavy objects, as this will shorten their lifespan.

5. If using multiple jacks simultaneously, maintain synchronized lifting speeds and ensure even load distribution on each jack to prevent tipping.

6. This jack uses 46# anti-wear hydraulic oil. Ensure the jack has sufficient filtered and clean working oil. Otherwise, the rated lifting height will not be achieved. It is recommended to change the oil after the first 3 months of use, and then every 6 months thereafter.

7. The cylinder should be lubricated regularly, which can be added through the air inlet.

8. Avoid sudden vibrations during use.

Common Troubleshooting Methods for Horizontal Hydraulic Jacks

Minor faults·Easy to diagnose·Simple to repair·Easy to operate

| Phenomenon | Analysis of causes | Elimination methods | |

| 1 | Oil leakage at the bottom | ① There was lubricating oil in the cylinder; this phenomenon only occurred during the previous use.

② Oil leakage was caused by the jack tipping over. |

You can continue using the jack; do not tip it over. |

| 2 | Oil leakage at the lifting switch | Too much oil added | You can continue to use it. |

| 3 | Hydraulic cylinder cannot rise to the top | Fuel tank low on oil | Add appropriate amount of hydraulic oil |

| 4 | Hydraulic cylinder does not rise or rises very slowly | ① This phenomenon is more common in winter

② The oil inlet pipe is stuck ③ The bead on the top left of the block is stuck |

After changing the hydraulic oil for winter use, open the valve, remove the bearings, and reinstall them. |

| 5 | Hydraulic cylinder does not lower after rising | ① Low air pressure

② Intake pipe or fuel line kinked |

Use after straightening if the concentration is greater than 0.8 MPa. |

| 6 | Automatic lowering after support | Oil leakage from the side beads of the cube | Disassemble, clean the beads, and reassemble. |